Auto Services

Nano Diamond Coating

Nano Diamond Coating are not ceramic coatings. We have created nanodiamond and polymer composites that outperform today’s ceramic coatings in ways that makes this a breakthrough technology.

Nano Diamond Coating technology has revolutionized the way the world’s hardest inorganic polymer (perhydropolysilazane – PHPS) is used. We invented a breakthrough method to merge a matrix of enriched nanodiamonds with inorganic PHPS to create a flexible coating appropriate for cars.

Nano Diamond Coating offers breakthrough technology for both consumers and professional automotive detailers:

Ease of Use – our products are easier to use than existing technologies, quickly inspiring confidence during the application process.

Nano Diamond Coating offers breakthrough technology for both consumers and professional automotive detailers:

Ease of Use – our products are easier to use than existing technologies, quickly inspiring confidence during the application process.

Nano Diamond Coating are based on an innovative combination of enriched nanodiamonds and perhydropolysilazane (PHPS).

Diamonds are the hardest natural material on the planet. When reduced down to nano size and enriched, they can be blended with polymers. Diamond ProTech has mastered the mixing of enriched nanodiamonds and PHPS to create an evenly distributed, diamond armored, elastic coating with inherent hydrophobic characteristics.

Perhydropolysilazane is the hardest of transparent silicon-based polymers that cure at natural temperatures. It is heat- resistant, UV-resistant, water-repellent, and provides the highest surface hardness and abrasion resistance that technology can offer. Inorganic versions will not react with organic elements, thereby reducing corrosion.

Diamonds are the hardest natural material on the planet. When reduced down to nano size and enriched, they can be blended with polymers. Diamond ProTech has mastered the mixing of enriched nanodiamonds and PHPS to create an evenly distributed, diamond armored, elastic coating with inherent hydrophobic characteristics.

Perhydropolysilazane is the hardest of transparent silicon-based polymers that cure at natural temperatures. It is heat- resistant, UV-resistant, water-repellent, and provides the highest surface hardness and abrasion resistance that technology can offer. Inorganic versions will not react with organic elements, thereby reducing corrosion.

Efficient Application Process

Faster curing times allow for quicker turnaround time.

Heat and UV-resistant Hydrophobic

Amazing water repellency that lasts.

True 9H Hardness

Highest abrasion resistance that technology can offer.

Ecologically Cleaner

Minimal environmental impact.

Tactile Feel

Super Smooth! Like no other product on the market today.

Our enriched nanodiamond coatings fill the micropores of your vehicle’s body, creating a smooth, even surface armed with millions of nanodiamond particles locked in a molecular matrix anchored on the car’s clearcoat. Whether on a car body or its windows, the dirt and water repellency performance provided by Diamond ProTech coatings will amaze you.

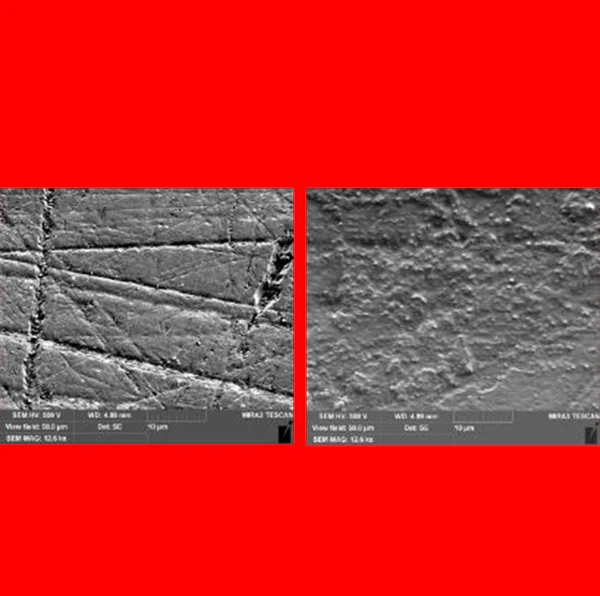

Surface view of car paintwork before and after Diamond ProTech coating.

Studies were carried out using a high resolution Tescan® Mira LMU electron microscope

Surface view of car paintwork before and after Diamond ProTech coating.

Studies were carried out using a high resolution Tescan® Mira LMU electron microscope

Nano Diamond Coating have been tested and verified by SGS (sgs.com) the world’s leading independent test company. They documented that nanodiamonds, enriched by our proprietary processes, take on superhydrophobic characteristics on top of what hydrophobic characteristics that PHPS already provides.

The pictures on the right show a 142° contact angle of a drop of water on enriched nanodiamond particles.

Measurement of the contact angle on enriched nanodiamonds

Hydrophobic properties of nanodiamonds were evaluated using an OCA 20 tensiometer (DataPhysics Instruments GmbH). Nanodiamonds were applied to the paper and liquid (distilled water, T = 24 °C ), V drop = 6 μl

The pictures on the right show a 142° contact angle of a drop of water on enriched nanodiamond particles.

Measurement of the contact angle on enriched nanodiamonds

Hydrophobic properties of nanodiamonds were evaluated using an OCA 20 tensiometer (DataPhysics Instruments GmbH). Nanodiamonds were applied to the paper and liquid (distilled water, T = 24 °C ), V drop = 6 μl

Nano Diamond Coating are designed with the professional detailer in mind. Our products combine ease of application and high performance without compromising either characteristic. We have engineered our coatings to flash slowly enough to allow a very controlled and stress-free application process. No need to worry about difficult to remove high spots ever again!

ACCELERATED CURING TIME

Many coatings use solvents which evaporate slowly forcing the coated car to be kept for up to 24 hours in a controlled environment so that the coating polymers can bond to the car body. Diamond ProTech coatings are engineered to minimize downtime during the application process. We use the cleanest, fastest-evaporating solvents, allowing the polymers to quickly bond with the car body which almost immediately solidifies into the protective layer.

Cars can be prepped, coated and returned to customers in the same day.

ACCELERATED CURING TIME

Many coatings use solvents which evaporate slowly forcing the coated car to be kept for up to 24 hours in a controlled environment so that the coating polymers can bond to the car body. Diamond ProTech coatings are engineered to minimize downtime during the application process. We use the cleanest, fastest-evaporating solvents, allowing the polymers to quickly bond with the car body which almost immediately solidifies into the protective layer.

Cars can be prepped, coated and returned to customers in the same day.

EFFICIENT LAYERING AND THICKNESS

Nano Diamond Coating are so superior, they don’t require more than one application layer. Yet multiple layering provides additional benefits. Some customers may want a deeper finish or even longer performance. For those situations, Diamond ProTech offers professional detailers the most efficient layering in the industry. Many other products have solvent bases which will partially degrade the previous coating on application so in the end, you only end up with an additional 20% – 50% of thickness after two layers are applied. Diamond ProTech uniquely offers 1:1 layering.

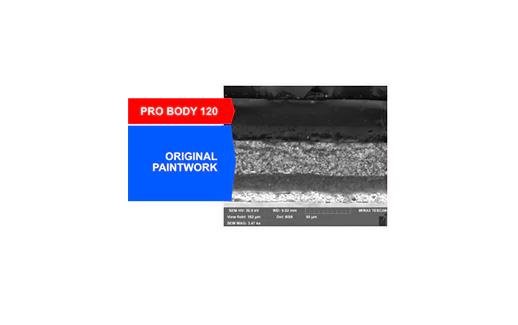

These measurements done under a Tescan® scanning electron microscope shows a sample of a car body with factory paint coated with our Diamond Pro Body 120 package.

Measurements were done on coated and uncoated panels to retrieve the coating thickness measurement.

DIamond ProTech coatings do not degrade their base coatings so that two layers results in a full 2x coating!

DIamond ProTech coatings do not degrade their base coatings so that two layers results in a full 2x coating!

PROVEN HARDNESS FROM INDEPENDENT LABS

In the coating industry, a product’s hardness or ability to resist scratches can be measured by the Pencil Scale. Diamond ProTech Nanodiamond Technology has been tested and verified by SGS, the world’s leading testing and certification company.

SGS Test Results:

Diamond ProTech nanodiamond coatings have been certified to achieve a Pencil Scale Hardness of 9H.

Tests: Pencil Scale Hardness Test – ASTM D3363.

FAQS

Diamonds rank as the toughest natural substance on Earth. When scaled down to a nano dimension and enhanced, they can merge with polymers. Diamond ProTech has perfected the art of combining these fortified nanodiamonds with PHPS, resulting in a uniform, diamond-reinforced elastic coating that naturally repels water.

If you’ve opened a Diamond ProTech product and tightly closed the cap, its shelf life is estimated to be around 6-12 months. We strongly advise against leaving the bottle open, as doing so will considerably diminish the product’s shelf life in an opened container.

Get your free estimate